Todo lo que Debes Saber sobre las Hojas de Cuchillo Utilitario con Recubrimiento de Titanio

Share

When it comes to utility knife blades, durability and performance are non-negotiable. Whether you’re a DIY enthusiast working on home projects, a professional handling heavy-duty tasks, or just someone who values efficiency, titanium-plated utility knife blades are the perfect solution. These blades are engineered for superior performance, extended lifespan, and resistance to wear and corrosion.

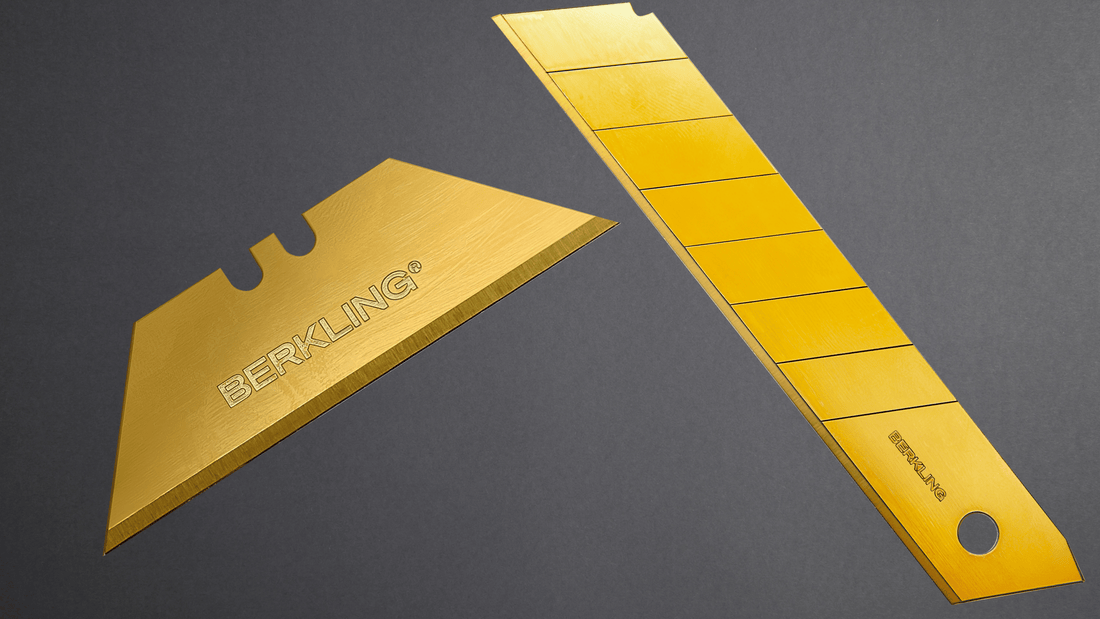

In this post, we’ll focus on two popular types of titanium-plated utility knife blades: razor blades (T-shape blades) and 18 mm snap-off knife blades. We’ll explore their benefits, applications, and maintenance tips to help you choose and use the right utility knife blade for your needs.

What Are Titanium-Plated Utility Knife Blades?

Titanium-plated utility knife blades are crafted with a layer of titanium coating applied to the steel blade. This titanium layer significantly enhances the blade’s durability and resistance to corrosion while maintaining its sharpness for a longer period compared to standard utility knife blades.

Key Features of Titanium-Plated Utility Knife Blades

- Enhanced Durability: Titanium’s strength adds an extra layer of resilience to the blade, making it last longer even under heavy use.

- Corrosion Resistance: The titanium coating protects the steel core from rust and other environmental factors, ideal for wet or humid conditions.

- Sharp Edge Retention: These utility knife blades stay sharper longer, reducing the need for frequent replacements.

- Compatibility: Designed to fit most standard utility knives, making them versatile for various applications.

Common Types of Titanium-Plated Utility Knife Blades

1. Razor Blades (T-Shape Blades)

Razor blades, also known as T-shape blades, are perfect for precision cutting tasks. Their flat, double-sided design makes them ideal for:

- Scraping: Removing stickers, paint, or adhesives from glass and smooth surfaces.

- Precision Cuts: Trimming thin materials like paper, fabric, and film.

- DIY Projects: Perfect for crafting or detailed work requiring sharp, clean edges.

2. 18 mm Snap-Off Utility Knife Blades

Snap-off utility knife blades are versatile, multi-segmented blades designed for heavy-duty use. Each segment can be snapped off to reveal a fresh, sharp edge. These utility knife blades are great for:

- Construction Work: Cutting drywall, insulation, and vinyl flooring.

- Packaging: Opening heavy-duty packaging or cutting cardboard.

- Long-Term Use: With multiple segments, these blades offer extended usability without requiring sharpening.

Why Choose Titanium-Plated Utility Knife Blades?

Titanium-plated utility knife blades offer several advantages that make them a superior choice for a range of tasks.

1. Superior Performance for Diverse Applications

- Home Projects: Perfect for tasks like cutting wallpaper, trimming carpet, or slicing cardboard for crafts.

- DIY Enthusiasts: Ideal for woodworking, model building, and other precision tasks where clean cuts are crucial.

- Commercial Use: Designed for industrial and professional settings, including packaging, roofing, and construction.

2. Cost Efficiency

Although titanium-plated utility knife blades may have a higher upfront cost, their extended lifespan reduces the need for frequent replacements, saving money in the long run.

3. Safety and Reliability

A sharper, more durable blade ensures smoother cuts and reduces the risk of slipping or accidents caused by dull edges.

Applications of Titanium-Plated Utility Knife Blades

1. Razor Blades (T-Shape Blades)

- Scraping paint, glue, or decals from windows and mirrors.

- Precision trimming of thin materials like film, vinyl, or delicate paper.

- Detailed craftwork and small-scale DIY projects.

2. 18 mm Snap-Off Utility Knife Blades

- Cutting through tough materials like drywall, plastic, or carpet.

- Heavy-duty packaging tasks in commercial environments.

- Scoring and slicing tasks in construction and renovation projects.

Choosing the Right Replacement Titanium-Plated Utility Knife Blades

When it’s time to replace your utility knife blades, opting for titanium-plated replacements is a wise investment. Here’s how to choose the right ones:

1. Consider Blade Compatibility

- Ensure the replacement blades match your knife’s specifications. T-shape blades and 18 mm snap-off utility knife blades fit specific knife types, so check your tool before purchasing.

2. Assess Task Requirements

- For precision work, choose razor blades for their accuracy and sharpness.

- For heavy-duty tasks, go with 18 mm snap-off utility knife blades for their strength and convenience.

3. Check Blade Packaging

- Many titanium-plated utility knife blades come in bulk packs, which are cost-effective for frequent users.

Maintenance Tips for Titanium-Plated Utility Knife Blades

Even the toughest utility knife blades require proper care to maximize their lifespan. Follow these simple tips to keep your titanium-plated utility knife blades in top condition:

1. Clean After Use

- Wipe the blade with a soft cloth to remove debris or residue. Use a mild cleaning solution for sticky substances.

2. Store Properly

- Keep utility knife blades in a dry, secure case to prevent damage and exposure to moisture.

3. Handle with Care

- Always wear gloves when handling utility knife blades to prevent accidental cuts.

4. Sharpen Only When Necessary

- While titanium-plated utility knife blades maintain sharpness longer, you can use a sharpening stone if needed. Focus only on the cutting edge to preserve the titanium coating.

How to Sharpen Titanium-Plated Utility Knife Blades

While titanium-plated utility knife blades are designed to stay sharper longer, they may eventually require sharpening for optimal performance. Here’s a step-by-step guide:

1. Gather the Right Tools

- Sharpening stone or honing tool

- Blade holder or guide to maintain the proper angle

- Safety gloves to protect your hands

2. Prepare the Blade

- Remove the blade from the utility knife to ensure safe handling.

- Clean the blade to remove any debris or residue before sharpening.

3. Set the Angle

- Hold the blade at a consistent 20-30 degree angle against the sharpening stone or tool. This angle ensures an effective edge without damaging the titanium coating.

4. Sharpen the Edge

- Use smooth, even strokes along the edge of the blade. Apply light pressure to avoid stripping the titanium coating.

- Flip the blade and repeat on the other side for an evenly honed edge.

5. Clean the Blade Again

- After sharpening, wipe the blade clean to remove any metal particles. Inspect the edge to ensure it’s sharp and even.

Pro Tip: Only sharpen utility knife blades when absolutely necessary, as excessive sharpening can wear down the titanium coating.

Frequently Asked Questions

1. Are titanium-plated utility knife blades worth the investment? Yes! Their durability, corrosion resistance, and longer edge retention make them cost-effective and reliable for various tasks.

2. Can I use titanium-plated utility knife blades for cutting metal? While these utility knife blades can score thin metal sheets, they’re not designed for cutting thick metal. Use specialized tools for heavy-duty metalwork.

3. How long do titanium-plated utility knife blades last? The lifespan depends on usage and care, but they typically outlast standard steel utility knife blades by 3-5 times under similar conditions.

4. Are these utility knife blades compatible with all utility knives? Most titanium-plated utility knife blades are designed to fit standard utility knives. Always check the product specifications for compatibility.

5. Can I recycle old titanium-plated utility knife blades? Yes, but ensure they’re disposed of in blade-specific recycling containers for safety and environmental responsibility.

Conclusion

Titanium-plated utility knife blades are a smart choice for anyone who values durability, precision, and long-term cost savings. Whether you’re a DIY enthusiast, a homeowner, or a professional in a demanding industry, these utility knife blades are built to tackle your toughest tasks with ease.

Ready to upgrade your utility knife game? Explore our range of titanium-plated T-shape razor blades and 18 mm snap-off utility knife blades, and experience the difference in performance and reliability. Don’t settle for ordinary—choose titanium for cutting-edge excellence!