Welcome to the World of Soldering Irons

Share

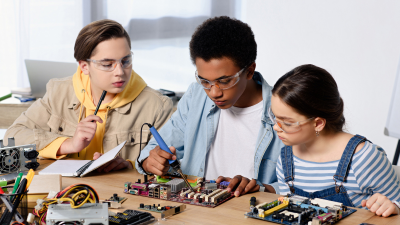

As an enthusiast and advisor in the world of electronics, I am here to guide you through the intricate process of choosing the right soldering iron for your electronic projects. Soldering irons are essential tools for anyone working with electronics, whether you're a hobbyist or a professional. In this article, we will explore the different types of soldering irons, factors to consider when choosing one, and provide recommendations for the best soldering irons available in the market. So let's dive in and unravel the secrets of soldering!

What is a Soldering Iron?

At its core, a soldering iron is a hand tool used for melting solder, a metal alloy, to join electronic components together. The soldering iron consists of a heated metal tip that transfers heat to the solder, allowing it to flow and create strong electrical connections. It is an indispensable tool for various applications such as circuit board assembly, wire repairs, and intricate soldering tasks.

Different Types of Soldering Irons

Soldering irons come in various types, each designed for specific purposes. The three most common types are:

1. Pencil Soldering Irons: These are lightweight, handheld soldering irons resembling a pen or pencil. They are versatile and suitable for general electronic soldering tasks.

2. Soldering Stations: Soldering stations consist of a base unit connected to a soldering iron via a cable. They offer precise temperature control, making them ideal for professional use or delicate soldering operations.

3. Butane-Powered Soldering Irons: Portable and cordless, these soldering irons are powered by butane gas. They are perfect for on-the-go soldering needs or situations where a power outlet is not readily available.

Factors to Consider When Choosing a Soldering Iron

Selecting the right soldering iron for your electronics projects involves considering several crucial factors. Let's explore them in detail:

Wattage and Temperature Control

One of the key factors to consider is the wattage of the soldering iron. Higher wattage generally means the iron heats up faster and can maintain a stable temperature when soldering larger components or working with thick wires. However, for delicate electronic work, a lower wattage iron is preferable to prevent damage to sensitive components.

Temperature control is also vital, especially when working with temperature-sensitive components. Look for soldering irons that offer adjustable temperature settings, allowing you to customize the heat based on the requirements of your project.

Tip Size and Shape

The size and shape of the soldering iron tip play a significant role in the quality of solder joints. For precision work, a fine and pointed tip is essential to access tight spaces and create precise connections. On the other hand, larger tips are better suited for soldering larger components or making strong connections.

Consider the type of soldering you will be doing and choose a soldering iron with interchangeable tips to accommodate different tasks effectively.

Power Source and Cord Length

Depending on your workspace and project requirements, you need to decide between corded or cordless soldering irons. Corded irons provide a consistent power supply but may limit your mobility. Cordless irons, powered by batteries or butane, offer portability but may have limitations in terms of continuous usage time.

Additionally, ensure the soldering iron's cord length is sufficient for your workspace. A longer cord provides flexibility and reduces the risk of accidents caused by limited movement.

Best Soldering Irons for Electronics

Now that we have a good understanding of soldering irons and the factors to consider, let's explore some of the top recommendations for soldering irons suitable for electronics projects:

1. Berkling BSG-668KR Butane Soldering Iron Kit

Features and Benefits:

- The soldering iron in this kit has a temperature range from 492-932ºF / 250-500ºC, while the torch offers a temperature up to 23720ºF / 1300ºC and the heat blower up to 1022ºF / 550ºC. The soldering iron also comes with a pure plated copper tip, which is shaped from a copper bar and coated with a protective iron coating. This tip offers efficient thermal recovery and good heat conductivity, making it ideal for use in various applications, such as electronics, computer, drone, circuit board, light welding, brazing, hobbies, light culinary tasks, plumbing, crafts, and wood burning. It includes a 1.6mm conical tin-coated tip, and the tip's thickness provides durability.

- The soldering iron kit also comes with an adjustable flame offering infinite heat output and temperature control with a slider from minimum to maximum. It features a retractable metal stand, a fuel chamber, and a protective cap to prevent damage to nearby surfaces and objects. The kit includes a soldering iron gun (red), 1.6mm conical, 2.4 chisel, heat deflector, mini wrench, and 15g 60/40 rosin core solder wire. Additionally, it includes a carrying case, making it easy to transport and store. The kit's soldering iron performance ranges from 30W to 125W equivalent electrical power and has an operating time of up to 125 minutes with the medium setting, but depends on the function and amount of heat output. The soldering iron size is 9.87”x1.18”x0.98” / 251x30x25mm with a protective cap and 9.65"x1.18"x0

Berkling BSG-810 Soldering Torch Kit

Features and Benefits:

- BERKLING focuses on providing professional soldering and welding equipment and accessories whose purpose is to make your work easier without compromising your safety or comfort. We rely on the highest quality materials and innovative manufacturing technologies to bring at your doorstep a wide range of tools that will never disappoint in terms of functionality and performance Not completely satisfied with your order? Don’t worry, we are always at your service to address any issues or concerns.

- Our butane torch lighter kit is a must-have for every professional, as it can be used for a wide range of purposes as a soldering iron, heat blower or torch. The torch kit includes various accessories that you can use for soldering, welding, repairing, or detailing but also for cooking and other DIY projects. Our butane torch doesn’t require electricity to work and only a butane refill that can last up to 1.5-2 hours! Super easy to operate and quick to heat up, this hand torch will become your favorite tool in your workshop!

Berkling BSG-568KR Soldering Iron Kit

Features and Benefits:

- 3 function in 1 unit - Butane solder iron, micro gas torch, heat blower gun. Ideal for both professional and home hobbyist to use on light to medium tasks and projects. A handy and versatile tool suitable for various type of applications such as melting solder wire, acrylic painting with torch flame, repair electrical wire, heat shrink tubing, working with fine jewelry and crafts, home DIY, repair electronics printed circuit board and computer motherboard and more.

- Butane gas powered - Does not require electricity or battery to operate. Great tool for tasks are out in the fields and places have no electricity. Rechargeable in less than 20 seconds and can operate up to 90 mins with a single full recharge. Use only premium lighter butane fuel to ensure the optimum performance and longer life the unit.

Tips for Using a Soldering Iron Effectively

Using a soldering iron requires skill and precision. Here are some essential tips to help you achieve excellent soldering results:

Prepare Your Workspace

Before you start soldering, ensure your workspace is clean, well-lit, and organized. Keep flammable materials away and have a fire-safe surface to place the soldering iron when not in use. Having a soldering station with a built-in stand or a separate stand for the iron will prevent accidents and damage to your work area.

Cleaning and Tinning the Tip

Always keep your soldering iron tip clean for optimal performance. Wipe the tip with a damp sponge or use a specialized tip cleaner to remove any residue. Additionally, regularly apply a thin layer of solder to the tip (a process called "tinning") to enhance heat transfer and prevent oxidation.

Soldering Techniques

Mastering different soldering techniques will greatly improve your results. Some commonly used techniques include through-hole soldering, surface mount soldering, and drag soldering. Practice these techniques and learn how to control the solder flow to create reliable and aesthetically pleasing joints.

Safety Precautions

Working with a soldering iron involves potential hazards, so it's crucial to prioritize safety. Here are some important safety precautions to follow:

Working in a Well-Ventilated Area

Soldering generates fumes that can be harmful when inhaled. Ensure you work in a well-ventilated area or use a fume extraction system to remove the soldering fumes effectively. Protecting your respiratory health is essential during any soldering activity.

Proper Handling and Storage

Always handle the soldering iron with care, especially when it's hot. Use heat-resistant gloves if necessary and avoid placing the iron on flammable surfaces. When not in use, store the soldering iron in a designated holder or stand to prevent accidental burns or damage.

Use of Safety Equipment

Wear safety goggles to protect your eyes from solder splashes or debris. Additionally, consider using heat-resistant mats or pads to protect your workspace from heat damage. It's better to be safe and well-prepared before starting any soldering project.

Conclusion

Congratulations! You have now gained valuable insights into the world of soldering irons for electronics. Remember to consider factors such as wattage, temperature control, tip size, and power source when choosing a soldering iron. Based on our recommendations, select a soldering iron that aligns with your project requirements and skill level. By following proper soldering techniques and adhering to safety precautions, you'll be well-equipped to tackle your electronic projects with confidence.

FAQs

Q: Can I use any soldering iron for electronics?

A: While some soldering irons are versatile and can handle various tasks, it's best to use a soldering iron specifically designed for electronics. These irons offer precise temperature control and fine tips, allowing for delicate soldering work.

Q: How do I choose the right wattage for my soldering iron?

A: Consider the size and complexity of the electronic components you'll be working with. Smaller components and intricate soldering require lower wattage, while larger components may necessitate higher wattage irons.

Q: What is the purpose of tinning the soldering iron tip?

A: Tinning the tip helps improve heat transfer and prevents oxidation. It creates a thin layer of solder on the tip, facilitating the flow of heat to the solder joint and ensuring a reliable connection.

Q: Can I solder without using flux?

A: Flux is essential for removing oxidation and improving solder flow. While some solder wires come with flux cores, it's generally recommended to use additional flux for cleaner and more effective soldering.

Q: What other tools do I need for soldering electronics?

A: Apart from a soldering iron, you may need additional tools such as solder wire, flux, desoldering pump or braid, wire cutters, tweezers, and helping hands with clips. These tools will assist you in various aspects of the soldering process, making your work more efficient and precise.