Soldering Iron for Guitar: The Perfect Tool for Precision and Quality

Share

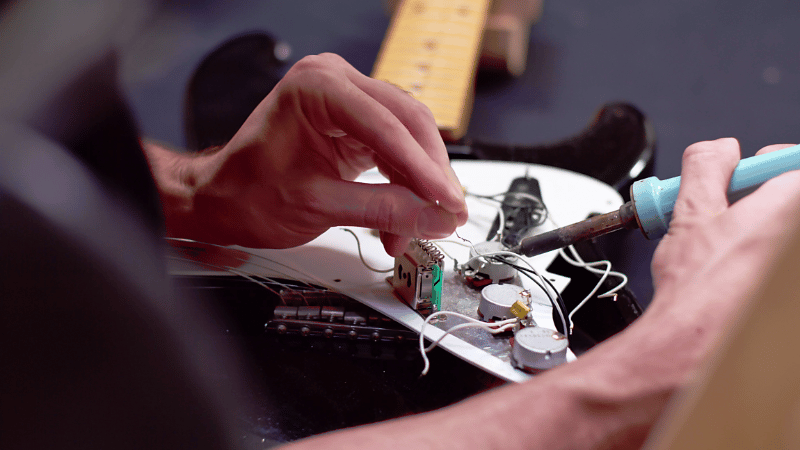

As an avid guitar enthusiast and advisor, I can confidently say that having a high-quality soldering iron is essential for anyone who wants to delve into guitar electronics and make their own modifications or repairs. A soldering iron is a tool used to join different metal components by melting and applying solder. When it comes to the intricate world of guitar wiring, having the right soldering iron can make a world of difference in the quality and longevity of your connections. In this article, I'll guide you through the process of choosing the best soldering iron for guitar and provide helpful suggestions based on my experience and expertise.

Importance of a Good Soldering Iron for Guitar

Types of Soldering Irons

When it comes to soldering irons for guitar work, there are several types available on the market. Let's explore the three main types:

Basic Soldering Irons

Basic soldering irons are the most affordable option and are suitable for occasional guitar soldering tasks. They usually come with a fixed wattage and limited temperature control. While they can get the job done, they lack the precision and consistency of higher-end models. If you're a beginner or on a tight budget, a basic soldering iron can be a good starting point.

Temperature-Controlled Soldering Irons

Temperature-controlled soldering irons provide precise control over the heat, allowing you to dial in the perfect temperature for specific soldering tasks. These irons typically have interchangeable tips and adjustable wattage, making them versatile and suitable for a wide range of guitar electronics projects. Investing in a temperature-controlled soldering iron is a wise choice for enthusiasts who value precision and flexibility.

Cordless Soldering Irons

Cordless soldering irons offer portability and convenience. They are powered by rechargeable batteries or butane gas, eliminating the need for a power outlet. While they may not reach the same levels of heat as their heavy duty corded counterparts, they are ideal for on-the-go repairs and quick touch-ups. Cordless soldering irons are handy additions to any guitarist's toolkit.

Factors to Consider When Choosing a Soldering Iron for Guitar

When selecting a soldering iron for guitar work, it's important to consider various factors to ensure you make the right choice. Here are some key considerations:

Power and Wattage

The power and wattage of a soldering iron determine how quickly it can heat up and maintain the desired temperature. For guitar soldering, a wattage range of 20-60 watts is generally sufficient. Higher wattage irons heat up faster, but they can also pose a higher risk of overheating delicate guitar components. Strike a balance between power and precision based on your specific needs.

Temperature Control

Temperature control is crucial when working with guitar electronics, as different soldering tasks require different temperature settings. Look for a soldering iron with adjustable temperature control to ensure you can match the right temperature to the job at hand. This feature allows for precise soldering and reduces the risk of damaging sensitive guitar parts.

Tip Variety and Interchangeability

Guitar soldering often involves working with different-sized components and tight spaces. Having a soldering iron with a variety of tip sizes and shapes allows for greater versatility and accessibility. Look for models that offer interchangeable tips, enabling you to customize the tool based on the task you're performing.

Heating Time and Recovery

Efficiency and time-saving are important factors to consider. A soldering iron with a fast heating time and quick recovery ensures that you can work without unnecessary delays. Look for irons with rapid heating elements and excellent heat recovery to maximize your productivity and minimize downtime.

Ergonomics and Comfort

Soldering guitar components can be a delicate and intricate process, often requiring steady hands and precise movements. Choosing a soldering iron with an ergonomic design and a comfortable grip can make a significant difference in your soldering experience. Look for models that provide a comfortable grip and reduce hand fatigue during extended soldering sessions.

Tips for Soldering Guitar Components

Now that you have chosen the right soldering iron for your guitar work, let's dive into some essential tips for soldering guitar components effectively:

Prepare the Workstation

Before starting any soldering project, it's crucial to set up a clean and organized workstation. Clear the area of any clutter, ensure good lighting, and have all the necessary tools and components within reach. A well-prepared workstation helps prevent accidents and allows for a focused and efficient soldering process.

Clean the Guitar Components

Cleanliness is vital when it comes to soldering guitar components. Make sure to remove any dirt, grease, or oxidation from the surfaces you'll be soldering. Use isopropyl alcohol and a clean cloth to wipe the components clean. Clean surfaces ensure better conductivity and stronger solder joints.

Secure the Wires

Properly securing the wires before soldering is essential for reliable connections. Use a hand tool or a heat-resistant clamp to hold the wires in place during the soldering process. This ensures stability and prevents any unintentional movements that could weaken the solder joint.

Apply Heat and Solder

Once everything is in place, it's time to apply heat and solder. Heat the soldering iron to the appropriate temperature for the task at hand. Place the tip of the iron on the joint, ensuring it contacts both the component and the wire. Allow the joint to heat up for a few seconds before applying a small amount of solder to the joint. The solder should flow smoothly and evenly around the joint.

Insulate and Test

After soldering the joint, it's essential to insulate it properly to prevent any short circuits or accidental contact with other components. Use heat shrink tubing, electrical tape, or insulating sleeves to cover the soldered area. Once the insulation is in place, perform a thorough test to ensure the solder joint is secure and functioning correctly.

Common Mistakes to Avoid

While soldering guitar components, it's crucial to avoid common mistakes that can compromise the quality of your work. Here are some pitfalls to watch out for:

Overheating the Guitar Components

Applying excessive heat to guitar components can cause irreversible damage. Overheating can melt plastic parts, warp circuit boards, or even burn delicate wires. Always ensure you're using the appropriate temperature and avoid prolonged contact between the soldering iron and the components.

Insufficient Heat or Solder

Insufficient heat or solder can result in weak and unreliable connections. Make sure to heat the joint adequately to ensure proper solder flow. Similarly, use enough solder to create a robust joint without excess. A good solder joint should be shiny and evenly distributed around the connection.

Poor Wire Connections

Properly stripping and tinning the wires before soldering is essential for strong connections. Ensure the wires are clean, tinned, and securely fastened before soldering. Loose or improperly stripped wires can lead to weak connections or intermittent signal issues.

Using the Wrong Tip Size

Using the wrong tip size can make soldering guitar components challenging and imprecise. A tip that is too large may make it difficult to access tight spaces, while a tip that is too small may not provide enough heat for larger joints. Choose a tip size that suits the specific task at hand to ensure accuracy and efficiency.

Maintenance and Care for Soldering Irons

To prolong the lifespan and ensure optimal performance of your soldering iron, it's important to practice proper maintenance and care. Here are some essential tips:

Cleaning the Tip

Regularly clean the tip of your soldering iron to remove any solder residue or oxidation buildup. Use a damp sponge or brass wire cleaner to gently wipe the tip while it's hot. Keeping the tip clean ensures better heat transfer and prevents oxidation, allowing for consistent and reliable soldering.

Storage and Protection

After each use, store your soldering iron in a dedicated holder or stand to protect it from damage. Make sure the iron has cooled completely before storing it to avoid any accidents. Additionally, consider investing in a protective carrying case or bag if you often transport your soldering iron.

Replacing Tips

Over time, soldering iron tips may wear out or become less effective. It's important to replace worn or damaged tips to maintain optimal soldering performance. Consult the manufacturer's guidelines to determine the appropriate replacement tips for your specific model.

Regular Calibration

Some soldering irons may require periodic calibration to ensure accurate temperature control. Check the user manual or manufacturer's instructions for any calibration recommendations. Proper calibration guarantees consistent and reliable heat output, minimizing the risk of overheating or cold solder joints.

Conclusion

A reliable soldering iron is a valuable tool for any guitar enthusiast or technician. It allows for precise soldering, strong connections, and the ability to customize and repair your instrument. By considering factors such as power, temperature control, tip variety, and ergonomics, you can choose the perfect soldering iron for your guitar projects. Remember to follow best practices, avoid common mistakes, and maintain your soldering iron properly to ensure consistent performance and longevity.

FAQs

Q: Can I use a regular soldering iron for guitar work?

A: While a regular soldering iron can be used for guitar work, it may lack the necessary precision and temperature control required for delicate guitar components. Investing in a soldering iron specifically designed for guitar work ensures better results and minimizes the risk of damage.

Q: What is the ideal temperature for soldering guitar components?

A: The ideal soldering temperature for guitar components typically ranges between 350°C and 400°C (660°F and 750°F). However, the specific temperature may vary depending on the type of solder, the components, and the task at hand. Always refer to the manufacturer's recommendations for optimal soldering temperatures.

Q: How often should I replace the tip of my soldering iron?

A: The frequency of tip replacement depends on various factors, including the type of soldering iron, frequency of use, and the soldering techniques employed. As a general guideline, consider replacing the tip when it becomes excessively worn, corroded, or fails to transfer heat efficiently.

Q: Can I solder my guitar without prior experience?

A: Soldering guitar components requires a certain level of skill and knowledge. If you're new to soldering, it's advisable to practice on scrap wire or less valuable components before working on your guitar. Additionally, seeking guidance from experienced guitar technicians or attending soldering workshops can help you develop the necessary skills.

Q: What should I do if I accidentally damage a guitar component while soldering?

A: Accidents can happen even to experienced soldering enthusiasts. If you accidentally damage a guitar component, assess the extent of the damage. In some cases, the damaged component may need to be replaced. Consult a professional guitar technician if you're uncertain or uncomfortable performing the repairs yourself.