A Beginner Guide of Gas Soldering Iron

Share

Introduction

As an enthusiastic soldering iron user and advisor, I'm here to share my knowledge and offer helpful suggestions about gas soldering irons. In this article, we will explore the world of gas soldering irons, their advantages, types, how they work, and their common applications. Whether you're a DIY enthusiast, a professional technician, or someone looking to delve into soldering projects, gas soldering irons can be an excellent addition to your toolkit.

What is a Gas Soldering Iron?

A gas soldering iron is a versatile tool used for soldering and desoldering electronic components. Unlike traditional electric soldering irons that rely on a direct power source, gas soldering irons are powered by butane gas. This innovative design allows for increased portability and flexibility in various soldering applications.

Gas soldering irons consist of a refillable gas canister that is connected to the iron itself. The butane gas stored in the canister is released and ignited within the iron's chamber, producing a flame that heats up the soldering tip. The heat from the flame then transfers to the tip, allowing it to melt solder and create electrical connections.

The portability of gas soldering irons makes them incredibly convenient for soldering tasks in different environments. Whether you are working outdoors, in tight spaces, or in remote locations without access to electricity, a gas soldering iron provides the freedom to solder wherever and whenever needed.

Gas soldering irons come in various sizes and designs, ranging from compact pen-style irons to larger, more robust models. Some irons offer adjustable temperature settings, allowing users to control the heat output based on the specific soldering requirements of their projects. Additionally, certain models feature interchangeable tips, providing versatility for different soldering tasks and component sizes.

The use of gas soldering irons is not limited to electronic repairs or installations. They are also popular among jewelry makers, hobbyists, automotive technicians, and craftsmen. The ability to achieve high temperatures quickly, combined with the precision control, makes gas soldering irons well-suited for intricate jewelry soldering, automotive wiring repairs, and a wide range of crafting projects.

Overall, gas soldering irons provide a portable, efficient, and reliable solution for soldering needs. Their ability to operate without relying on a direct power source, quick heating time, and versatility in various applications make them an invaluable tool for soldering enthusiasts, professionals, and anyone in need of a reliable soldering solution on the go.

Advantages of Gas Soldering Irons

Gas soldering irons offer several distinct advantages over their electric counterparts, making them a popular choice among soldering enthusiasts. Let's explore the benefits that make gas soldering irons stand out:

- Portability: One of the key advantages of gas soldering irons is their portability. They are not bound by electrical cords or the need for a power outlet, allowing users to solder in remote locations, outdoor settings, or confined spaces where access to electricity may be limited or unavailable. Whether you're working on a DIY project outdoors, repairing electronics on the go, or soldering in unconventional environments, a gas soldering iron provides the freedom and mobility to work wherever needed.

- Quick Heating: Gas soldering irons heat up rapidly, significantly reducing the waiting time before you can start soldering. The butane gas fuel quickly ignites and generates a flame that efficiently heats up the soldering tip. This quick heating feature allows you to jump straight into your soldering tasks without wasting precious time, increasing your overall productivity and efficiency.

- High Temperature Capability: Gas soldering irons are capable of reaching higher temperatures compared to many electric soldering irons. The increased temperature range allows for effective soldering and desoldering of a wide variety of components, including those that require more heat to achieve proper solder flow. This makes gas soldering irons particularly useful for projects involving heavy-duty or thick wires, larger solder joints, or intricate components that demand precise temperature control.

- Versatility: Gas soldering irons are versatile tools suitable for a range of soldering applications. Their compact size and lightweight design make them ideal for intricate soldering tasks that require precision and maneuverability. Whether you're working on delicate electronics, jewelry making, circuit board repairs, or even automotive soldering, gas soldering irons offer the flexibility to handle various projects with ease.

- No Power Cord Limitations: Unlike electric soldering irons that require a power cord, gas soldering irons provide unhindered movement and flexibility during soldering. With no cord limitations, you can easily navigate around objects or work in tight spaces without the hassle of managing cords or worrying about tangling. This freedom of movement contributes to improved accuracy and control over your soldering work.

- Independence from Power Outages: Gas soldering irons prove to be reliable tools during power outages or in areas with unstable electricity supply. Whether you're in a remote location, on-site for repairs, or facing unexpected power disruptions, a gas soldering iron ensures you can continue with your soldering tasks without interruptions. This reliability is particularly valuable in critical situations or time-sensitive projects.

- Ease of Use and Maintenance: Gas soldering irons are generally straightforward to use, with user-friendly ignition mechanisms and intuitive controls for adjusting the flame or gas flow. Refilling the gas canister is a simple process, allowing you to replenish your fuel supply when needed. Additionally, gas soldering irons require minimal maintenance, typically involving regular cleaning of the soldering tip to ensure optimal heat transfer and occasional replacement of worn-out or damaged parts.

Types of Gas Soldering Irons

When it comes to gas soldering irons, there are several types available on the market, each catering to specific soldering needs and preferences. Let's explore some of the common types of gas soldering irons:

- Basic Gas Soldering Irons: These are the standard gas soldering irons that offer a simple yet effective solution for soldering tasks. They typically consist of a pen-shaped design with a built-in gas canister and a soldering tip. Basic gas soldering irons are compact, lightweight, and easy to use, making them suitable for general soldering applications and small-scale projects.

- Adjustable Temperature Gas Soldering Irons: These gas soldering irons come with temperature control features, allowing users to adjust the heat output based on their specific soldering requirements. They often feature a control knob or buttons to set the desired temperature. This flexibility makes adjustable temperature gas soldering irons versatile for working with different types of solder and components that may demand specific temperature ranges for optimal soldering results.

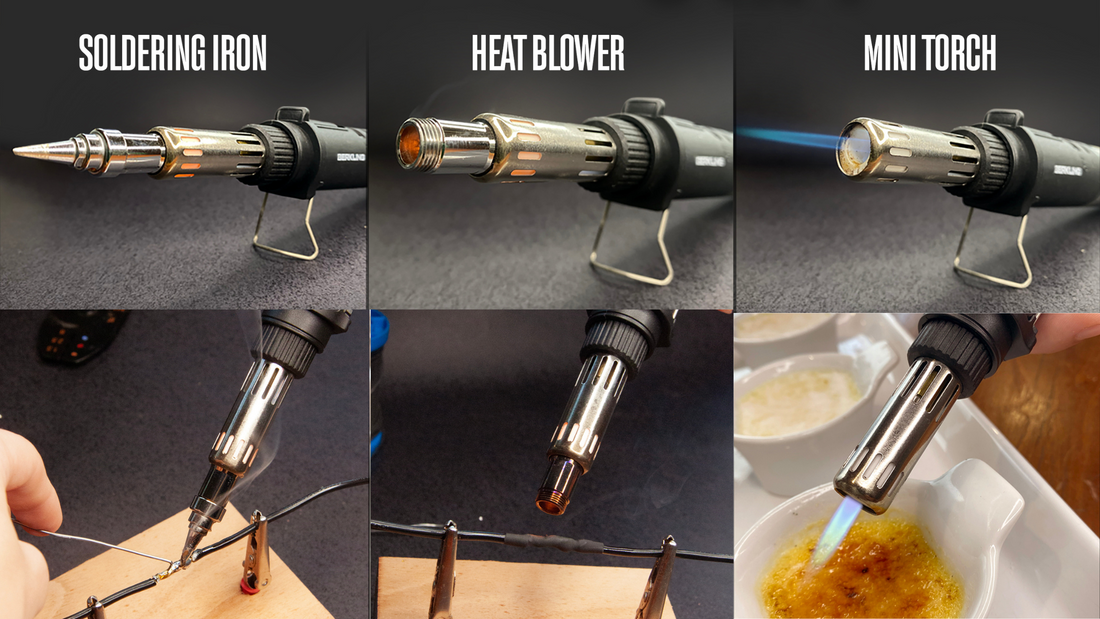

- Butane Torch Soldering Irons: Butane torch soldering irons combine the functionality of a soldering iron with that of a torch such as Berkling BSG-2000. They feature a broader flame tip, providing a more intense heat source suitable for larger solder joints, brazing, or heat-shrink tubing applications. These versatile tools are useful for tasks that require both soldering and localized heating, such as plumbing repairs, jewelry making, or automotive soldering.

- Cordless Gas Soldering Irons: Cordless gas soldering irons offer the ultimate freedom of movement and portability. These irons utilize a separate gas canister and soldering iron unit, allowing users to work without the restrictions of a cord. Cordless gas soldering irons are especially beneficial for soldering in tight spaces, intricate electronics, or when maneuverability is crucial. They eliminate the inconvenience of managing cords and provide flexibility in various soldering environments.

- Interchangeable Tip Gas Soldering Irons: Interchangeable tip gas soldering irons are designed with versatility in mind. They feature a system where the soldering tips can be easily swapped out to accommodate different soldering tasks and component sizes. This allows users to select the appropriate tip for specific soldering requirements, such as fine-point tips for delicate electronics or chisel tips for larger connections. Interchangeable tip gas soldering irons provide convenience and adaptability, minimizing the need for multiple soldering tools.

- Refillable Gas Soldering Irons: Refillable gas soldering irons come with a refillable gas canister, allowing users to replenish the fuel supply when needed. These irons often have a transparent window or indicator to monitor the gas level, ensuring you are aware of when it's time for a refill. Refillable gas soldering irons provide cost-effectiveness and sustainability since you can reuse the canister instead of relying on disposable cartridges.

How Does a Gas Soldering Iron Work?

Gas soldering irons operate on a simple yet efficient mechanism that allows for effective soldering and desoldering of electronic components. Understanding how a gas soldering iron works can help you make the most of this versatile tool. Let's delve into the inner workings of a gas soldering iron:

At the core of a gas soldering iron is a refillable gas canister. This canister is filled with butane gas, a highly flammable fuel commonly used in portable gas-powered tools. The canister is connected to the soldering iron itself, usually through a tube or gas line.

When the gas soldering iron is ignited, either manually or through an ignition mechanism, the butane gas is released from the canister and flows into the iron's chamber. Inside the chamber, the gas is mixed with air, creating a combustible mixture.

With the mixture ready, the gas soldering iron has a built-in ignition source, such as a piezoelectric ignition system or a flint ignition mechanism. Activating the ignition source produces a spark, igniting the combustible gas-air mixture within the chamber.

Once ignited, the gas-air mixture generates a flame that provides the heat required for soldering. This flame is directed towards the soldering tip, which is usually made of a conductive material, such as copper or iron, capable of retaining and transferring heat effectively.

The heat from the flame is transferred to the soldering tip, causing it to reach high temperatures. The heated tip melts the solder, a metal alloy with a low melting point, allowing it to flow and create electrical connections between components. The molten solder adheres to the surfaces being soldered, creating a strong and reliable joint.

To control the heat output, gas soldering irons typically have a gas flow control feature. This control can be in the form of a lever, a dial, or a switch, allowing users to adjust the amount of gas being released into the chamber. By regulating the gas flow, you can control the intensity of the flame and, consequently, the heat generated by the soldering tip.

Gas soldering irons offer a rapid heating process, allowing you to start soldering tasks almost instantly. The high temperatures achieved by the flame enable efficient soldering of various components, ranging from small, delicate electronics to larger wires and connectors.

It's important to note that gas soldering irons require proper ventilation due to the combustion process and the production of fumes. Working in a well-ventilated area or using a fume extractor helps ensure a safe working environment and prevents the buildup of potentially harmful gasses.

Benefits of Using a Gas Soldering Iron

Using a gas soldering iron offers several distinct benefits that make it a valuable tool for soldering and desoldering tasks. Whether you're a professional technician, an electronics enthusiast, or a hobbyist, understanding the advantages of a gas soldering iron can help you make informed decisions and achieve optimal soldering results. Let's explore the benefits:

- Portability and Mobility: One of the primary advantages of a gas soldering iron is its portability. Unlike electric soldering irons that require a direct power source, gas soldering irons are powered by butane gas, allowing you to work without constraints in various environments. Whether you're working on projects outdoors, in remote locations, or in tight spaces where access to electricity may be limited, a gas soldering iron provides the freedom to solder wherever and whenever needed. The absence of power cords enhances mobility and maneuverability, enabling you to work with ease.

- Quick Heating and Rapid Start-up: Gas soldering irons heat up quickly, significantly reducing the waiting time before you can start soldering. When ignited, the butane gas flame generates intense heat that rapidly transfers to the soldering tip. This quick heating feature allows you to jump straight into your soldering tasks without wasting precious time. Whether you're tackling time-sensitive projects or simply aiming to improve efficiency, the rapid start-up time of a gas soldering iron ensures that you can begin soldering promptly.

- High Temperature Capability: Gas soldering irons are capable of reaching higher temperatures compared to many electric soldering irons. This high-temperature capability is advantageous when working with components or soldering joints that require elevated temperatures for proper solder flow. The ability to reach these higher temperatures ensures efficient and reliable soldering results, particularly for applications involving heavy-duty or thick wires, larger solder joints, or intricate components that demand precise temperature control.

- Versatility in Soldering Applications: Gas soldering irons are versatile tools suitable for a wide range of soldering applications. They excel in various fields, including electronics repair, jewelry making, automotive repairs, and crafting hobbies. The precise control over the heat output allows for intricate and delicate soldering tasks, making gas soldering irons popular among electronics enthusiasts. Additionally, their quick heating time and portability make them indispensable for soldering tasks in automotive repairs and crafting projects, where flexibility and mobility are key.

- Independence from Power Sources and Outages: Gas soldering irons provide independence from reliance on electrical power sources. This feature is particularly advantageous when working in areas with unstable electricity supplies or during power outages. Whether you're on remote job sites, in outdoor locations, or facing unexpected power disruptions, a gas soldering iron ensures uninterrupted soldering operations. This reliability and independence enable you to work with confidence, knowing that you can continue soldering without being hindered by power constraints.

- Ease of Use and Control: Gas soldering irons are generally user-friendly and easy to control. They typically feature intuitive ignition mechanisms, such as piezoelectric ignition systems or flint ignition, which make them easy to start and operate. Many gas soldering irons also offer adjustable gas flow control, allowing users to regulate the heat intensity by controlling the amount of gas released into the chamber. This control over the heat output enables precise soldering and enhances overall soldering performance.

- Compact Size and Lightweight Design: Gas soldering irons are known for their compact size and lightweight design. This makes them comfortable to hold and maneuver during soldering tasks. The compact size is particularly advantageous when working in tight spaces or on intricate projects where precision is crucial. The lightweight nature of gas soldering irons minimizes fatigue during extended soldering sessions, allowing you to work for longer periods without discomfort.

- Suitable for Outdoor and On-the-Go Soldering: Gas soldering irons are ideal for outdoor and on-the-go soldering needs. Whether you're working on automotive repairs, field electronics, or remote installations, a gas soldering iron provides the flexibility and reliability to handle soldering tasks in outdoor environments. The portability and quick heating time allow for efficient soldering in various weather conditions and remote locations, empowering technicians and enthusiasts to accomplish soldering tasks wherever they are.

- Sustainability and Cost-Effectiveness: Gas soldering irons often utilize refillable gas canisters, which contribute to sustainability and cost-effectiveness. Instead of relying on disposable cartridges, you can refill the gas canisters, reducing waste and overall soldering costs in the long run. Refillable gas canisters are widely available, making it convenient to keep a steady supply of fuel for your soldering iron.

Tips for Choosing the Right Gas Soldering Iron

To ensure you select the right gas soldering iron for your needs, consider the following tips:

- Consider the temperature range: Opt for an iron that offers a temperature range suitable for your soldering requirements.

- Evaluate the tip variety: Look for models that come with interchangeable tips to accommodate different soldering tasks.

- Check for adjustable gas flow: Having control over the gas flow allows you to regulate the heat output, ensuring precise soldering.

- Consider ergonomics: Choose an iron with a comfortable grip and a well-balanced design to minimize fatigue during extended soldering sessions.

- Read customer reviews: Research and read reviews to get insights from other users about the performance and durability of different gas soldering irons.

Proper Safety Precautions

When working with gas soldering irons, it's crucial to prioritize safety. Here are some essential safety precautions to follow:

- Work in a well-ventilated area: Ensure there is proper air circulation to prevent the accumulation of fumes.

- Use protective gear: Wear safety glasses and heat-resistant gloves to shield yourself from potential hazards.

- Keep a fire extinguisher nearby: In case of emergencies, have a fire extinguisher within reach.

- Store gas canisters properly: Store gas canisters in a cool, dry place, away from direct sunlight and sources of heat.

- Turn off the gas: After use, turn off the gas flow and allow the iron to cool down before storing it.

Maintenance and Care

To prolong the life of your gas soldering iron and ensure optimal performance, follow these maintenance and care tips:

- Clean the tip: Regularly clean the soldering tip to remove any residue or oxidation, ensuring better heat transfer.

- Refill gas canisters: Keep spare gas canisters handy to refill the iron when necessary.

- Inspect and replace worn-out parts: Check the iron's components regularly and replace any damaged or worn-out parts.

- Store in a protective case: When not in use, store the gas soldering iron in a protective case to prevent damage and maintain its condition.

Common Applications of Gas Soldering Irons

Gas soldering irons find applications in various fields, including:

- Electronics repair: Gas soldering irons are widely used for repairing circuit boards, soldering surface mount components, and reworking electronic devices.

- Jewelry making: Their precise control and portability make gas soldering irons suitable for intricate jewelry soldering tasks.

- Automotive repairs: Gas soldering irons are handy for repairing wiring, soldering connectors, and fixing electrical components in vehicles.

- Crafting and hobbies: Whether you enjoy creating stained glass art or building model airplanes, gas soldering irons offer versatility for hobbyist projects.

Comparison with Electric Soldering Irons

While gas soldering irons have their advantages, it's essential to consider how they compare to electric soldering irons. Electric soldering irons offer consistent heat output, making them suitable for prolonged soldering sessions. They are also easier to control in terms of temperature settings. However, gas soldering irons excel in portability, versatility, and quick heating time, making them indispensable in certain situations.

Conclusion

Gas soldering irons offer unique advantages for soldering and desoldering tasks. Their portability, quick heating time, and versatility make them indispensable tools for both professionals and hobbyists. By following the tips for choosing the right gas soldering iron, practicing proper safety precautions, and maintaining the iron's condition, you can maximize your soldering experience. Embrace the convenience and flexibility that gas soldering irons provide, and unlock a world of creative possibilities.

FAQs

Q: Can I use a gas soldering iron for heavy-duty soldering projects?

A: While gas soldering irons can handle various soldering tasks, heavy-duty projects might require more power and sustained heat. Consider electric soldering irons for such applications.

Q: What is the average lifespan of a gas soldering iron?

A: The lifespan of a gas soldering iron depends on various factors, including usage frequency, maintenance, and build quality. With proper care, a high-quality gas soldering iron can last for several years.

Q: Are there any safety risks associated with gas soldering irons?

A: Gas soldering irons involve working with open flames and high temperatures. It's important to follow safety precautions, work in a well-ventilated area, and use protective gear to minimize risks.

Q: Can I use a gas soldering iron for delicate electronics?

A: Yes, gas soldering irons can be used for delicate electronics. However, it's crucial to exercise caution and control the heat output to prevent damage to sensitive components.

Q: Is it necessary to use a soldering station with a gas soldering iron?

A: While using a soldering station can provide additional stability and convenience, it's not always necessary. Gas soldering irons can be used independently without a soldering station, offering more flexibility in terms of portability and maneuverability.