Exploring the World of Solder: Types and Applications

Share

Introduction

Soldering, the art of joining metals by melting a filler material, has been an essential skill in various industries for centuries. Whether you're a DIY enthusiast, a professional engineer, a jewelry maker, or someone looking to understand the world of soldering, this comprehensive guide will take you on a journey through the diverse landscape of solder types and their applications.

Soldering is critical in electronics, plumbing, aerospace, jewelry making, and countless other fields. Selecting the correct solder type for your needs is crucial to achieving reliable and durable connections. This article delves into the nuances of various solder types, their compositions, advantages, disadvantages, and the best scenarios for their use.

Quick Tips for Successful Soldering

Before we dive into the world of solder types, let's start with some quick tips to help you achieve successful soldering results:

Safety First

- Always work in a well-ventilated area or use a fume extractor to avoid inhaling harmful fumes.

- Wear safety goggles to protect your eyes from splattering molten solder.

- Use heat-resistant gloves to prevent burns when handling hot soldering irons.

- Match your soldering iron's wattage to the job's requirements. Higher wattage is better for more extensive connections, while lower wattage suits delicate work.

- Ensure the soldering iron has a temperature control feature for precise soldering.

Prepare Your Workspace

- Clean the work area and ensure it's free from flammable materials.

- Use a soldering mat or a non-flammable surface to protect your workbench.

Properly Tin the Iron Tip

- Before soldering, apply a small amount of solder to the iron tip to ensure good heat transfer and prevent oxidation.

Use the Right Flux

- Select flux that matches your solder type for effective cleaning and fluxing of the joint.

Practice Good Technique

- Heat the workpiece, not the solder. Touch the solder to the joint, not the iron tip.

- Make sure the joint is clean, oxidation-free, and aligned adequately before soldering.

Avoid Overheating

- Prolonged exposure to high heat can damage components. Limit soldering time to avoid this.

Inspect Your Work

- After soldering, inspect the joint for proper wetting, smoothness, and a shiny appearance.

With these quick tips in mind, let's explore the fascinating world of solder types and their applications.

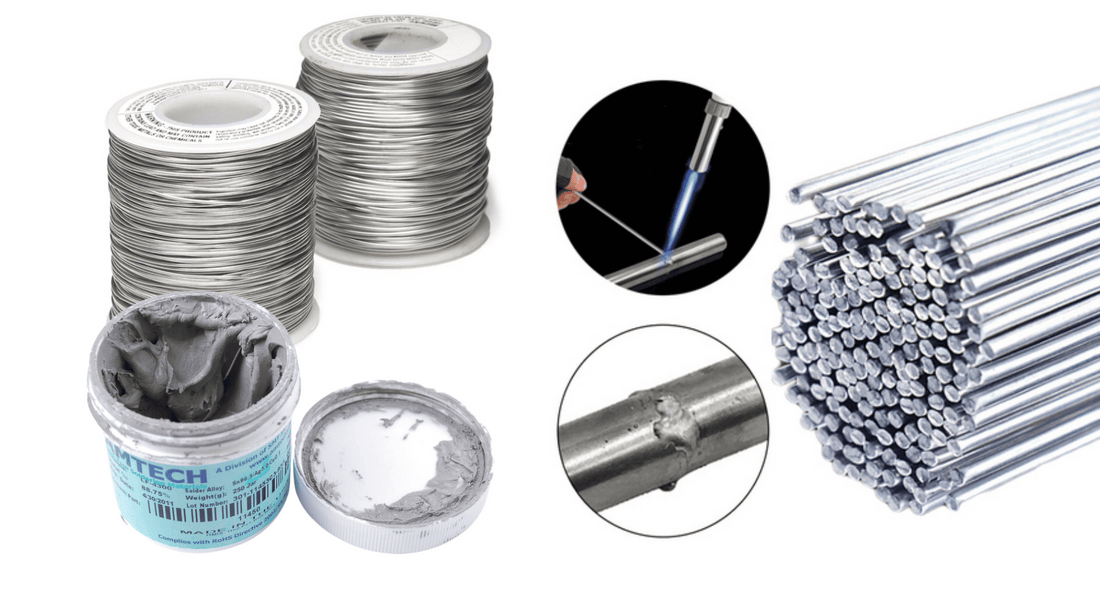

Types of Solder

Lead-Based Solder

Composition and Characteristics:

- Typically composed of tin and lead.

- Melts at lower temperatures, making it easier to work with.

- Known for its excellent wetting properties.

Advantages:

- Low melting point ensures less heat stress on components.

- Forms solid and reliable connections.

- Widely available and cost-effective.

Disadvantages:

- Contains lead, which poses environmental and health concerns.

- Limited use in industries due to environmental regulations.

Applications:

- Electronics soldering (before lead-free regulations).

- Plumbing for copper pipe joints.

Lead-Free Solder

Composition and Environmental Considerations:

- Typically consists of tin, silver, and copper, without lead.

- Meets environmental regulations, including RoHS (Restriction of Hazardous Substances).

Advantages:

- Environmentally friendly and safer for health.

- Complies with modern electronic manufacturing standards.

- Suitable for most electronic applications.

Disadvantages:

- Higher melting point compared to lead-based solder.

- Requires more precise soldering techniques.

Applications:

- Electronics manufacturing (in compliance with environmental regulations).

- General-purpose soldering.

Rosin-Core Solder

Composition and Flux Properties:

- Contains a core of flux, a substance that cleans and promotes solder flow.

- Flux options include rosin (tree sap) for electronics and acid for plumbing.

Suitable Applications and Soldering Techniques:

- Ideal for electronics soldering due to its non-corrosive nature.

- The flux core simplifies the soldering process, making it suitable for beginners.

Pros and Cons:

- Pros: Easy to use, suitable for most electronics.

- Cons: Limited to specific applications due to non-corrosive nature.

Flux-Cored Solder

Composition and Flux Options:

- Contains a flux core with various formulations to match different soldering needs.

- Flux options include no-clean, water-soluble, and more.

Ideal Scenarios for Flux-Cored Solder:

- Perfect for applications where additional flux is needed.

- Useful for soldering components with poor wetting properties.

Benefits and Limitations:

- Pros: Versatile and can be used in various applications.

- Cons: Some flux residues may require cleaning post-soldering.

Silver Solder

Composition and Characteristics:

- Contains a high percentage of silver.

- Requires higher temperatures for melting.

- Available in various silver content levels.

Applications:

- Jewelry making, particularly for silver jewelry.

- Plumbing for stainless steel and other metals.

- Electronics in specific high-temperature applications.

Advantages:

- Creates solid and durable joints.

- Suitable for high-temperature and high-stress environments.

- Offers excellent electrical conductivity.

Disadvantages:

- Higher melting points can be challenging to work with.

- Silver content makes it more expensive than other solder types.

Aluminum Solder

Composition and Unique Challenges:

- Formulated for soldering aluminum and aluminum alloys.

- Requires specialized techniques due to aluminum's oxide layer.

Applications:

- Aerospace industry for aluminum components.

- Automotive repairs on aluminum parts.

Tips for Successful Aluminum Soldering:

- Use flux designed explicitly for aluminum.

- Pre-clean aluminum surfaces to remove the oxide layer.

Solder Paste

Composition and Role in Surface Mount Technology (SMT):

- Consists of solder particles suspended in flux.

- Integral to the SMT assembly process for electronic components.

SMT Assembly Process:

- Applied to solder pads on a printed circuit board (PCB).

- Components are placed on the solder paste, and the entire assembly is reflowed in an oven.

Benefits and Challenges of Using Solder Paste:

- Pros: High precision, suitable for automated assembly.

- Cons: Requires specialized equipment and controlled environments.

Selecting the Right Solder for Your Application

Choosing the suitable solder for your application is essential to achieving quality results. Consider the following factors when making your selection:

Material Compatibility

Different solder types are better suited to certain materials. Ensure the solder you choose is compatible with the metals you'll join. For instance, lead-based solder may not be suitable for aluminum, while aluminum solder is designed for that purpose.

Melting Point and Working Temperature

Consider the melting point of the solder and whether it aligns with your application's requirements. Some solder types require higher temperatures, which may affect sensitive components or materials.

Environmental Regulations

Choosing solder that complies with relevant regulations is crucial for environmentally-conscious individuals and industries. Lead-free solder, for instance, meets modern environmental standards.

Safety Considerations

Soldering can be safe and enjoyable when the proper precautions are taken. Here are some essential safety considerations to keep in mind:

Health and Safety Precautions

- Always work in a well-ventilated area or use a fume extractor to remove harmful fumes and gases produced during soldering.

- Wear safety goggles to protect your eyes from splattering solder or flux.

- Use heat-resistant gloves to prevent burns when handling hot soldering irons or components.

Proper Ventilation and Protective Equipment

- Invest in a quality fume extractor or work near an open window to ensure proper ventilation.

- Use a soldering iron stand to secure the iron when not in use to prevent accidental burns or fires.

Compliance with Soldering Regulations

- Familiarize yourself with local, state, and national regulations regarding soldering, primarily if you work in industries with strict compliance requirements.

Table of Solder Types and Products (Amazon)

|

Solder Type |

Recommended Products |

Prices (Approximate) |

|

Lead-Based Solder |

$10 - $15 (1 lb roll) |

|

|

Lead-Free Solder |

$10 - $15 (1 lb roll) |

|

|

Rosin-Core Solder |

$8 - $12 (4 oz roll) |

|

|

Flux-Cored Solder |

$10 - $15 (0.5 lb roll) |

|

|

Silver Solder |

$20 - $30 (1/16" diameter) |

|

|

Aluminum Solder |

$5 - $10 (3-pack) |

|

|

Solder Paste |

$15 - $20 (1.2 oz syringe) |

Please note that prices may vary based on the seller and location. Always check the latest prices and read product reviews before making a purchase.

Conclusion

Soldering is a versatile and crucial technique in various industries, from electronics to plumbing, aerospace, and jewelry. Understanding the different types of solder, their compositions, advantages, and limitations is vital to achieving successful soldering results.

As you embark on your soldering journey, remember that safety should always be your top priority. Follow the recommended safety precautions and ensure compliance with any relevant regulations.

The world of soldering is continually evolving, with new materials and techniques emerging. Don't hesitate to explore and experiment with different solder types to discover the best fit for your projects. Whether you're a novice or an experienced soldering professional, there's always more to learn and find in the fascinating world of soldering.